PCB Component Assembly Technology-SMT And DIP

PCB Component Assembly Technology-SMT And DIP

Today’s society is a society dominated by electronic products, do you find that almost all electronic products contain a kind of device? That’s the PCB. With the continuous improvement of human requirements for electronic products, the use of printed circuit boards has become more and more mundane. Suffice it to say that pretty much everything electronics is included, including your PC, laptop, smartphone, game console, microwave, TV, dishwasher, and more. Turnkey PCB assembly companies assemble printed circuit boards using various processes. In this article, FS Technology will introduce you to the knowledge of circuit board assembly.

What is PCB Assembly

First of all, I would like to introduce some professional terms in the PCB industry:

- PCB: Abbreviation for Printed Wiring Board

- PCBA: Abbreviation for Printed Wiring Board

- SMT: Surface Mount Technology, a technology used in circuit board assembly

- THT: Through-hole technology, similar to SMT, but mainly for DIP plug-ins, which has been gradually phased out over time

If you’re in the circuit board assembly industry, these specialized terms make it a must, whether you’re interfacing with colleagues within a company or needing to communicate with manufacturers.

Here is a piece of cold knowledge, the original abbreviation of the printed circuit board is not PCB but PWB, because PWB has the same abbreviation as a hazardous substance and was renamed. (The editor of FS Technology forgot what substance it was)

As the best turnkey PCB company in China, FS Technology can produce almost all types of PCBs and possess all PCB assembly technologies.

So let me go back to the topic, printed circuit board assembly is the process of assembling electronic components to the bare board through various techniques of our common circuit bare boards. PCB components are involved in the entire assembly process. This is a non-linear process, and the turnkey assembly company has shown that the entire assembly process requires consideration of various factors, which can be changed and adjusted by the customer after the assembly process begins. Of course, before the start of the whole project, the customer needs to design the circuit board, and inform the PCB assembly company of the PCB schematic diagram, the electronic components to be used, and the expected functions. The final implemented function matches the components used on the PCBA board.

How circuit boards work

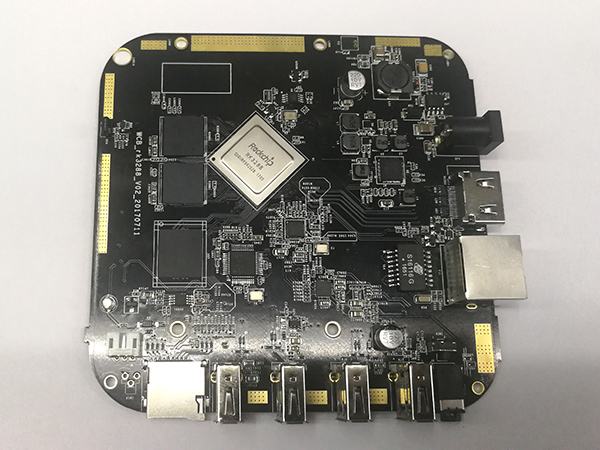

The bare PCB board itself cannot work, and the bare circuit board is combined with the PCB components through the assembly process to form a PCBA board, so as to work. PCBA can be regarded as a central hub, which connects the electronic components on the board through electrical connections. When we are creating a multilayer board assembly, electrical paths or circuits can be laminated to the substrate material. There are metal-colored lines on the PCBA board, which are copper traces made of copper. Its function is to provide electricity for electrical connections. After the PCB is soldered with electronic components, the copper traces act as a circuit for all components soldered to the board, thereby powering the device while providing isolation and safe current transfer.

PCB material preparation

The turnkey PCB assembly company will purchase electronic components in advance and prepare the materials required for assembly before carrying out the project. The following are the basic materials that need to be prepared by FS Technology:

Printed circuit board or substrate: the green board, if your chosen partner is a turnkey company like FS Technology, we can design and produce your circuit board for you.

Electronic components that need to be installed: This depends on what kind of equipment you will be applying the board to and the complexity of the equipment. For example, the PCBA of a radio is relatively simpler than that of a computer. FS Technology can completely solve these troubles for you. We can provide customers with assembly and PCB manufacturing services, and we can also provide PCB component procurement services.

Solder material: Solder wire, solder paste, preform and other welding materials are essential materials for PCB assembly. Its function is to accurately solder components to the bare PCB board. You can open your printed circuit and there will be grainy silver balls on it, that’s solder.

Soldering Equipment: Although the circuit board you see is small, its process is very complex and requires the use of various soldering equipment, including soldering stations, wave soldering machines, inspection, testing equipment and SMT equipment. The equipment that needs to be used depends on the specific project, for example, the reflow soldering process used in electronics is mainly vapor phase and infrared.

After preparing these most basic things, we can enter the specific link of circuit board assembly.

Methods of Mounting PCB Components

The technique used to assemble a circuit board and its various components is called mounting technology in circuit board assembly. Depending on factors such as application, cost and size, turnkey PCB manufacturers use different assembly techniques. The following concentrates are commonly used by FS Technology when completing projects.

Surface mount technology

The assembled PCBA board has different PCB components, one is plugged in and the other is attached using soldering techniques. Electronic components like chips are assembled using surface mount technology (FS Technology will use its acronym SMT instead for the sake of clarity). This placement technique was originally called “Flat Mount” and was used when we were working with SMD components. If you don’t understand the difference between SMT and SMD, you can read FS Technology’s blog post.

SMT assembly technology can increase board density and can be performed on smaller boards. With the pursuit of small electrical appliances, SMT assembly technology has gradually replaced through-hole technology (FS Technology will be replaced by its abbreviation THT hereinafter). Typically, SMT uses solder to connect components to the board, but in some cases adhesive dots can also be used on the second side to hold the components inside the reflow oven.

Through-hole technology

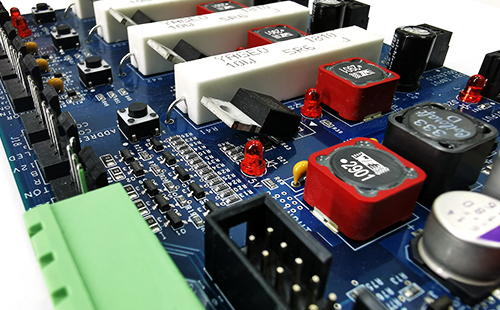

The abbreviation for through-hole assembly technology is THT, but most engineers call it DIP because DIP is more convenient than THT. Similar to the relationship between SMT and SMD, THT represents a PCB assembly technology, and DIP is a PCB plug-in. This technique works by making through holes in the board, then the turnkey company inserts the electronic components, and finally solders its pins on the other side of the pad. When you read the above text, you can probably guess why it was replaced by SMT. DIP assembly is very limited by the size of the board, and nowadays people prefer small and fully functional electronic devices.

Our traditional plug-in technology is a point-to-point structure, with through-holes becoming popular as double-sided and multi-layer boards become more popular. DIP assembly works by connecting components with conductive layers to ensure proper functioning of the circuit board. These components have leads to connect to the other side of the through-hole board.

In contrast to SMT methods, through-hole technology provides greater cohesion to the board assembly as components are placed through the board itself.

Electromechanical Assembly

Electro – Mechanical components use electrical and mechanical units to cover a wide range of functions such as generating electricity, controlling switches and other mechanical tasks. Because electromechanical components are often used in applications with complex wiring and assemblies, components need to be put together manually.

So it can often be time-consuming. Use this technique and break down the process into segments and use experts from each segment. Therefore, FS Technology can shorten the lead time.